Manufacturing Startup Cost Calculator

Calculate Your Manufacturing Startup Costs

Starting a manufacturing business isn’t like opening a coffee shop. You can’t do it with a few thousand dollars and a dream. But you also don’t need a million. The truth? Most small-scale manufacturers in North America launch with between $50,000 and $250,000. That’s the range where real production begins-no more prototypes, no more garage experiments. This is where you make product, sell it, and keep the lights on.

What You’re Really Paying For

People think manufacturing costs are just about machines. They’re not. The biggest chunk of your budget isn’t the equipment-it’s the space, the permits, the inventory, and the people. Let’s break it down.

First, space. A 2,000-square-foot industrial unit in a mid-tier city like Hamilton or Windsor costs about $1,500 to $2,500 a month. That’s rent. You’ll need at least 100 square feet per worker for safety and workflow. So if you plan to hire three people, you’re looking at 300 sq ft minimum. But you also need room for raw materials, finished goods, and loading docks. A 5,000 sq ft space? More realistic. That’s $3,500-$5,000/month.

Then there’s equipment. If you’re making plastic parts, a small injection molding machine runs $40,000-$80,000. CNC machines for metal? $60,000-$120,000. You don’t need top-of-the-line. Used equipment from auctions or bankruptcies can cut that in half. But even then, you’re looking at $25,000-$75,000 for one core machine. Add a laser cutter, a packaging line, and a forklift? Add another $30,000.

Raw materials? You’ll need 3-6 months of inventory before you start selling. If you’re making custom furniture, that’s $10,000-$30,000 in wood, hardware, and finishes. If you’re making soap or cosmetics? $5,000-$15,000 in oils, containers, labels. You can’t wait for orders to come in before you buy materials. That’s how you go broke.

Licensing and Compliance

You can’t just start building things and selling them. Every province has rules. In Ontario, you need a business license ($75-$250), a zoning permit ($200-$1,000), and if you’re handling chemicals or food-grade products, you need additional certifications. The Canadian Food Inspection Agency (CFIA) requires registration if you’re making anything edible. That’s $500-$2,000 just to file.

Then there’s liability insurance. $2,000-$5,000 a year. Workers’ comp? Mandatory if you hire anyone. That’s $1,500-$4,000/year depending on payroll. And if you’re shipping products? You need product liability coverage. That’s another $1,000-$3,000.

Don’t forget safety. OSHA-style rules apply here too. You need fire extinguishers, emergency exits, first-aid kits, and training logs. That’s $1,000-$3,000 upfront. And you’ll need to update it every year.

People Costs

One person can run a small shop-if they’re skilled. But you won’t be able to sell, make, and ship at the same time. Most new manufacturers hire one or two people right away.

Skilled machinists in Ontario make $22-$30/hour. Add benefits? That’s $50,000-$70,000 per person, per year. A part-time sales rep? $1,500-$3,000/month. You can start with freelancers, but you’ll need someone full-time by month six.

And don’t forget payroll taxes. In Canada, you pay 10.5% of gross wages in CPP and EI. That’s extra. So if you pay $60,000 to a worker, you’re actually spending $66,300.

Marketing and Sales

You can make the best product in the world, but if no one knows it exists, you’re out of business. Most small manufacturers underestimate this. You need a website. Not a fancy one. Just a simple Shopify or WooCommerce store with product photos, specs, and a contact form. That’s $1,500-$4,000.

Then there’s Google Ads. You’ll need to bid on keywords like “custom metal parts Ontario” or “small batch soap manufacturer.” That’s $500-$1,500/month. Trade shows? One local event costs $2,000-$5,000. You’ll need at least two a year.

And packaging. Custom boxes, labels, inserts? $0.50-$3 per unit. If you sell 1,000 units a month, that’s $500-$3,000 just in packaging. It adds up fast.

Real-World Examples

Here’s what three small manufacturers actually spent in 2025:

- Custom wooden cutting boards (Toronto): $78,000 total. $32,000 for a CNC router, $18,000 for raw maple and oil inventory, $12,000 for a 3,000 sq ft unit deposit, $8,000 for website and branding, $8,000 for insurance and permits.

- Small-batch herbal salves (Winnipeg): $42,000 total. $15,000 for lab-grade mixing equipment, $10,000 for organic oils and containers, $8,000 for CFIA registration, $5,000 for website and Amazon FBA setup, $4,000 for liability insurance.

- Plastic injection molding parts (Hamilton): $195,000 total. $110,000 for used injection molding machine, $25,000 for mold design and fabrication, $30,000 for 5,000 sq ft warehouse, $15,000 for two employees’ first three months, $15,000 for safety gear and training.

Notice anything? The cheapest startup didn’t skip permits. The most expensive didn’t buy new machines. They all had cash for at least six months of operating costs.

How to Start With Less

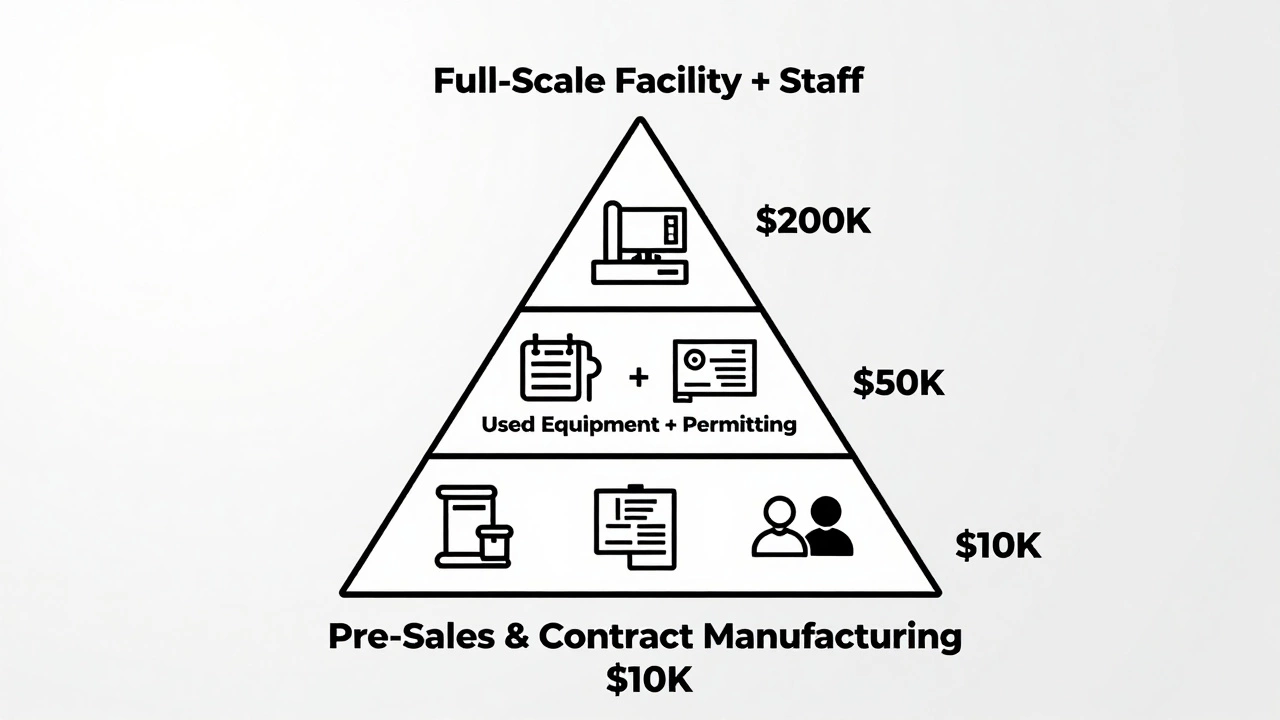

You don’t need to spend $200,000. But you need a plan.

- Start with contract manufacturing. Find a shop that already has the machines. Pay them per unit. You handle design and sales. This cuts your upfront cost to $10,000-$30,000.

- Use local maker spaces. Some have CNC machines, 3D printers, and laser cutters you can rent by the hour. Toronto has several. Pay $25/hour instead of $80,000 for a machine.

- Pre-sell. Use Kickstarter or Instagram to take orders before you build. That cash pays for materials. No inventory risk.

- Start with one product. Don’t try to make 10 things. One product. One market. One sales channel. Master it before you scale.

Where the Money Goes Wrong

Most small manufacturers fail because they spend too early. They buy the best machine. They lease a huge space. They hire two people before they have one customer.

Here’s what to avoid:

- Buying new equipment unless you’re certain you’ll use it 40+ hours a week.

- Signing a long-term lease without a revenue forecast.

- Waiting for “perfect” packaging or branding before you sell.

- Ignoring cash flow. You need 6 months of expenses saved before you open.

One guy in Kitchener spent $140,000 on a CNC mill, rented a 10,000 sq ft unit, hired three people, and had zero sales for nine months. He lost everything. He didn’t understand that manufacturing is a sales game first, a production game second.

Final Numbers: What You Really Need

Here’s the realistic breakdown for a lean, small-scale manufacturing startup in Canada in 2026:

| Category | Low End | High End |

|---|---|---|

| Space Deposit (3 months) | $4,500 | $15,000 |

| Core Equipment (used) | $15,000 | $75,000 |

| Raw Materials (3-6 months) | $5,000 | $30,000 |

| Licenses, Permits, Insurance | $3,000 | $10,000 |

| Website + Marketing (first 6 months) | $2,000 | $8,000 |

| First 3 Months Payroll (1-2 people) | $10,000 | $35,000 |

| Total | $39,500 | $173,000 |

That’s it. You can start for under $40,000 if you’re smart. You’ll need $150,000-$200,000 if you want to scale fast. But don’t let the high end scare you. Most people who succeed start on the low end and grow slowly.

Next Steps

Before you spend a dollar:

- Write down your exact product. Not a category. One thing. What is it? What materials? What size? Who buys it?

- Call three local machine shops. Ask if they’ll make your product for you. Get quotes.

- Find 10 people who’d buy it. Ask them: "Would you pay $25 for this?" If they say yes, write down why.

- Calculate your break-even. How many units do you need to sell to cover your monthly costs? If it’s 500, and you can’t sell 500 in 3 months, rethink.

Manufacturing isn’t about passion. It’s about numbers. Get the numbers right, and you’ll build something that lasts.

Can I start a manufacturing business with $10,000?

Yes-but only if you’re not making the product yourself. You can start a small manufacturing business with $10,000 by acting as a middleman. Find a contract manufacturer who already has machines and space. You handle design, branding, and sales. Use that $10,000 for samples, a website, and initial marketing. This model works well for custom apparel, small-batch cosmetics, or specialty hardware. But you won’t own equipment or a facility. That’s fine. Many successful manufacturers never bought a single machine.

Do I need a business license to start manufacturing?

Yes. Every province requires a general business license. If you’re making food, cosmetics, or medical devices, you’ll need additional approvals. In Ontario, you must register with the Ministry of Finance for HST, and if you’re handling chemicals or food, you may need a permit from local public health. Skipping this sounds like a cost saver-but it’s a legal risk. Fines can be $5,000-$50,000. It’s not worth it.

How long until a small manufacturing business breaks even?

Most take 8-18 months. The fastest break-even cases are those with pre-orders. If you sell 100 units before production starts, you’re already covered. If you’re waiting for customers to find you, it could take over a year. Your break-even point depends on your monthly fixed costs (rent, insurance, payroll) and your profit per unit. If you make $15 profit per item and your monthly costs are $6,000, you need to sell 400 units. At 50 units/month, that’s 8 months. At 20 units/month, it’s 20 months.

Is it better to buy new or used equipment?

Used. New equipment is 30-60% more expensive and comes with a 12-24 month warranty. Used equipment from a closing shop often has 2-3 years of life left and comes with a 90-day guarantee. Many sellers include training. A used CNC machine that’s five years old might cost $40,000 instead of $100,000. You’ll save $60,000 and still get reliable performance. Only buy new if you need cutting-edge precision or custom features.

Can I run a manufacturing business from home?

Sometimes. If you’re making soap, candles, or small wooden items, you might qualify under home-based business rules. But if you’re using loud machines, handling chemicals, or producing over 50 units a week, you’ll likely violate zoning laws. Most cities restrict manufacturing in residential zones. Check with your municipal office. Many small manufacturers start at home, then move to a shared industrial space after 6-12 months. It’s a smart way to test demand before committing to rent.

If you’re serious about starting, the best advice isn’t about money. It’s about starting small, validating demand, and scaling only when you have proof. The market doesn’t care how much you spent. It cares what you deliver-and how fast.