Manufacturing Startup Funding Calculator

Calculate Your Manufacturing Startup Funding Needs

Results

Securing funding for a manufacturing startup is tough. You need money for equipment, materials, and scaling production-often way more than a tech startup. But with the right approach, you can find the cash you need. Here’s exactly how.

Key Takeaways

- Manufacturing startups typically need $250K-$500K upfront, compared to $50K for software startups.

- Canada’s Industrial Research Assistance Program (IRAP) covers up to 70% of R&D costs for eligible projects.

- Pre-orders and crowdfunding can validate demand and fund initial production runs.

- A working prototype and clear supply chain plan are non-negotiable for investors.

- Common mistakes include underestimating equipment costs and ignoring supply chain risks.

Why Manufacturing Startups Need Different Funding Strategies

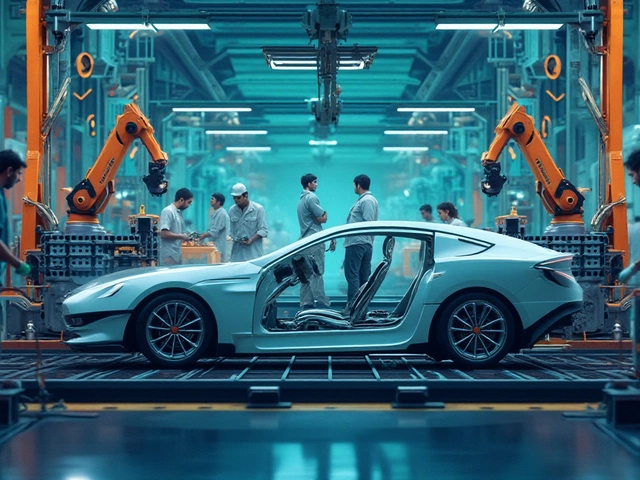

Unlike software companies that can launch with minimal upfront costs, manufacturing startups face high capital requirements. You need to buy machinery, source raw materials, and set up production facilities before selling anything. In Canada, the average manufacturing startup requires manufacturing startup funding of $250,000 to $500,000 just to get started. For example, a Toronto-based furniture manufacturer needed $320K for CNC machines, wood supplies, and a small factory lease. Without proper funding planning, most fail before they even begin production.

This means traditional startup advice-like bootstrapping or using credit cards-often doesn’t work. You need structured funding paths that match manufacturing’s unique challenges. Let’s look at the options available.

Leverage Government Grants and Subsidies

Canadian government programs can be a game-changer for manufacturing startups. The Industrial Research Assistance Program (IRAP) is a top choice. It offers non-repayable grants covering up to 70% of R&D costs for eligible projects. For instance, a small-scale metal fabricator in Hamilton used IRAP to fund a new welding robot, reducing their development costs by $120K.

Another option is the Ontario Manufacturing Acceleration Program (MAP), which provides grants for equipment purchases and process improvements. MAP covers up to 50% of costs up to $250K. A Toronto-based food processing startup used this to buy specialized packaging equipment, cutting production time by 40%.

Don’t overlook local programs too. Many cities offer grants for sustainable manufacturing or job creation. For example, Toronto’s Green Manufacturing Grant supports eco-friendly production methods with up to $50K in funding.

Build a Business Plan That Wins Investors

Your business plan isn’t just a formality-it’s your roadmap to funding. For manufacturing, it must include detailed technical specs, supplier relationships, and production costs. Investors will ask: "Can you actually make this product consistently?" So include things like:

- Machine specifications and costs (e.g., "CNC lathe: $45K, 2 units")

- Raw material suppliers and lead times (e.g., "Aluminum sheets from ABC Metals, 30-day lead time")

- Production capacity (e.g., "500 units/month at full capacity")

- Realistic financial projections (include costs for maintenance, training, and waste)

A Vancouver-based electronics manufacturer secured $300K from an angel investor by showing exact equipment costs and a 12-month production timeline. They proved they could hit targets without overpromising.

Find the Right Investors for Manufacturing

Most venture capital firms avoid manufacturing due to high risk and slow returns. But angel investors often specialize in physical product businesses. Look for angels with industry experience-like former factory owners or engineers. They understand the challenges.

Networking is key. Attend events like the Toronto Manufacturing Conference or Canadian Manufacturers & Exporters meetups. These events connect you with investors who’ve funded similar startups.

For example, a Hamilton-based textile startup raised $200K from a group of angel investors after demonstrating their prototype at a local trade show. They had a clear path to scale and a solid supplier network.

Use Pre-Orders and Crowdfunding to Fund Production

Crowdfunding isn’t just for tech gadgets. Manufacturing startups can use it to prove demand and fund initial production. Platforms like Kickstarter or Indiegogo work well, but you need a tangible prototype.

A Toronto-based home goods company raised $80K in 30 days by offering pre-orders for their new line of sustainable kitchenware. They shared detailed production plans and even showed a working prototype. This approach validated market interest before mass production.

Another tactic is direct pre-orders from customers. For example, a small furniture maker in Calgary sold 100 units before production started, covering 60% of their equipment costs. This reduced their financial risk significantly.

Avoid These Common Funding Mistakes

Many manufacturing startups fail because they skip critical steps. Here’s what to avoid:

- Underestimating equipment costs: A Montreal startup miscalculated machinery maintenance, leading to a $50K shortfall.

- Ignoring supply chain risks: A Quebec-based electronics company lost funding when their Chinese supplier delayed shipments by 6 months.

- Skipping the prototype: A Toronto-based medical device startup failed because they only had CAD designs.

Always get third-party quotes for equipment and materials. For example, a Hamilton-based metal fabricator saved 15% on machinery costs by comparing quotes from three suppliers before committing.

Frequently Asked Questions

Can I get funding without a prototype?

No. Investors and grant programs require a working prototype to validate your product. For example, IRAP requires a detailed technical plan and prototype testing results. A Toronto-based startup that tried to fund without a prototype lost all investor interest within 30 days.

How long does it take to secure government grants?

The timeline varies. IRAP applications take 2-3 months for approval, while provincial programs like MAP can take 4-6 months. Start early-apply 6 months before you need funds. A Hamilton-based manufacturer secured IRAP funding in 85 days by submitting complete documentation on the first try.

What’s the best way to approach angel investors?

Target angels with manufacturing experience. Research their past investments-look for companies in similar sectors. Prepare a 10-minute pitch that focuses on your prototype, supply chain, and scalability. A Toronto-based startup secured funding by showing exactly how their prototype solved a real industry pain point during a pitch event.

Do I need a business plan to get a grant?

Yes. Most grants require a detailed business plan including technical specifications, financial projections, and market analysis. For example, IRAP applications need a 15-20 page plan with clear milestones. A Montreal-based startup missed IRAP funding because their plan lacked cost breakdowns for equipment maintenance.

How much equity should I give up for funding?

For early-stage funding, you might give up 15-25% equity. Angel investors typically take 20% for $200K-$500K. Government grants usually don’t require equity. A Toronto-based startup retained 80% ownership by using a mix of grants and pre-orders before seeking investors.