Car Manufacturing in India: Growth, Trends & Opportunities

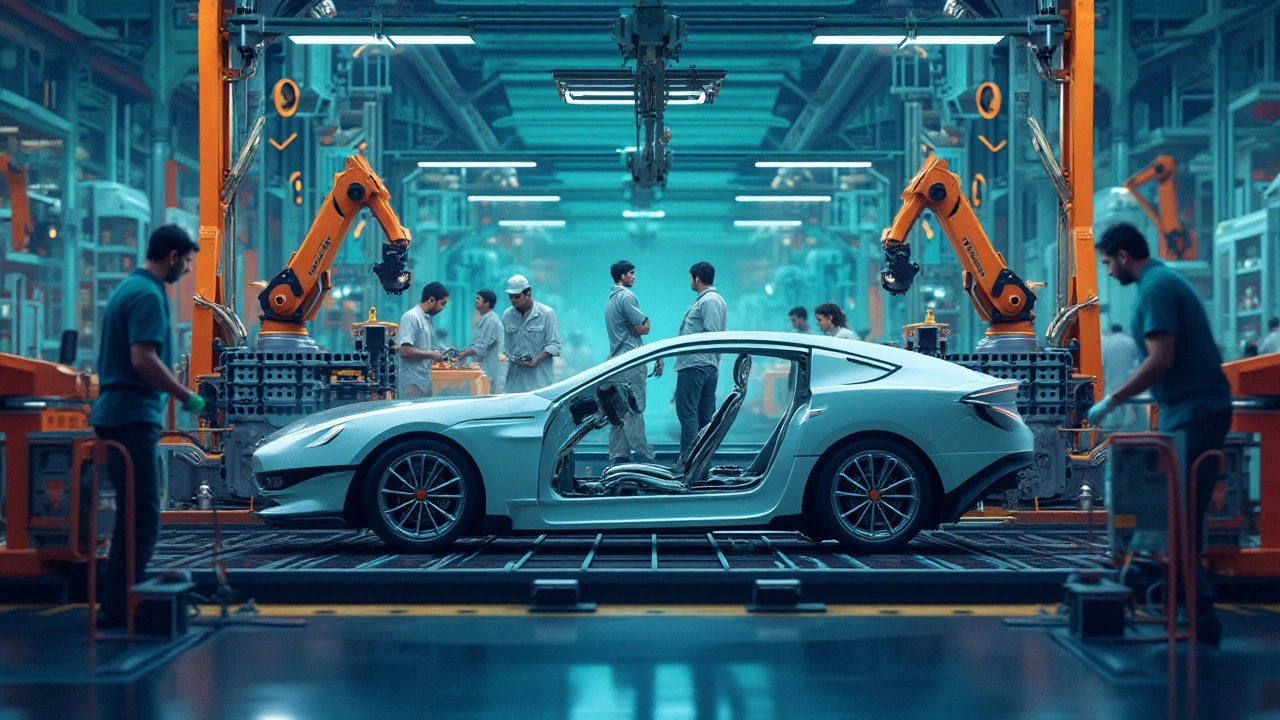

India’s auto scene is changing fast. From bustling factories in Gujarat to new electric‑vehicle (EV) lines in Karnataka, the country is turning into a major car‑making hub. If you’re curious about why this matters for shoppers, job seekers, or investors, you’re in the right spot.

Why India is Becoming a Car Hub

First off, the market size is huge. Over 30 million new cars roll off Indian roads each year, and that demand fuels local production. The government backs the sector with tax breaks, easier land acquisition, and a push for greener vehicles. Those policies lower costs for manufacturers and make it cheaper to set up new plants.

Second, labor costs stay low compared with China or Europe. Skilled workers in engineering and assembly are abundant, and many come from the country’s strong manufacturing tradition. That combo of cheap, capable labor helps keep prices down for buyers.

Third, the supply chain is maturing. Steel, plastics, and electronics suppliers have built regional clusters, especially around Chennai and Pune. When parts are close, lead times shrink and factories can respond quickly to changing demand.

Key Players and Upcoming Projects

Big names like Tata Motors, Mahindra & Mahindra, and Maruti Suzuki dominate the domestic market. They’ve all announced massive expansions, adding new capacity for SUVs, compact cars, and EVs. Foreign giants such as Hyundai, Kia, and Volkswagen also run large plants, often co‑locating with Indian firms to share technology.

One of the hottest projects right now is the EV corridor stretching from Gujarat to Tamil Nadu. Companies are setting up battery factories, charging‑infrastructure hubs, and the first fully Indian‑made electric sedan is slated for launch next year. That move could reshape the entire market and bring new jobs.

Start‑ups aren’t left out either. A handful of Silicon‑ Valley‑style firms are building low‑cost electric micro‑cars aimed at city commuters. They rely on 3‑D‑printed components and modular designs to keep prices under ₹5 lakhs.

For anyone watching the auto space, a few takeaways matter. Prices will likely stay competitive because manufacturers keep scaling up. Expect more electric options as the government pushes for 30 % EV sales by 2030. And job prospects in engineering, logistics, and software will keep growing as factories adopt smart‑manufacturing tools.

All that said, challenges remain. Infrastructure gaps, especially in ports and highways, can slow exports. And the global chip shortage still makes some production lines pause. Still, the momentum is strong, and India’s car‑making story is only getting started.

Top Exported Cars from India: A Comprehensive Guide

India has become a major hub for automobile manufacturing, exporting a wide range of vehicles to various countries worldwide. The country offers a competitive cost advantage and high-quality production standards, making it attractive for car manufacturers. Amongst the myriad of cars being manufactured, a select few have gained significant popularity in international markets. This article explores the most exported cars from India, highlighting key manufacturers and factors contributing to their global success.

View More