Ever bitten into a bag of chips and wondered how it all came together? That's where food units come into play. These units are the backbone of the food processing industry, taking raw ingredients and turning them into the shelf-stable products lining our grocery store aisles. From tiny artisan shops preserving fruity jams to massive facilities churning out ready meals, each food unit operates like a well-oiled machine to meet our demands.

So, what's a food unit exactly? Think of it as a factory or a processing plant, each specializing in a particular type of food production. Some deal with dairy, others with grains, and some are all about that savory, spicy sauce you love drizzling over your fries. They not only produce food but often mix, cook, pack, and handle it in ways that make the whole process efficient and safe. Curious how they keep everything running so smoothly and what it means for the stuff you eat? Stick around as we explore the nitty-gritty details of food units and why they matter more than you might think.

- Introduction to Food Units

- Different Types of Food Processing Units

- How Food Units Impact Quality and Safety

- Technological Innovations in Food Processing

- Challenges and Future of Food Units

Introduction to Food Units

Okay, so you've heard the term before but what exactly is a food unit? In the food industry, a food unit is crucial. These are specialized facilities that handle everything from grinding grains to canning soups. If you've ever eaten something processed, thank a food unit. They exist to transform raw materials into safe, consumable goods that are either fresh or have a longer shelf life.

Importance of Food Units

Why does it matter, you ask? Well, without food processing units, our access to diverse and packaged foods would be super limited. These units ensure that food gets processed quickly and efficiently. This means extending shelf life, improving safety, and sometimes even enhancing nutritional value. They're all about keeping our plates full while maintaining quality and safety standards.'

| Type | Function |

|---|---|

| Canning Units | Preserve fruits and vegetables |

| Dairy Processors | Produce milk products like cheese and yogurt |

How They Operate

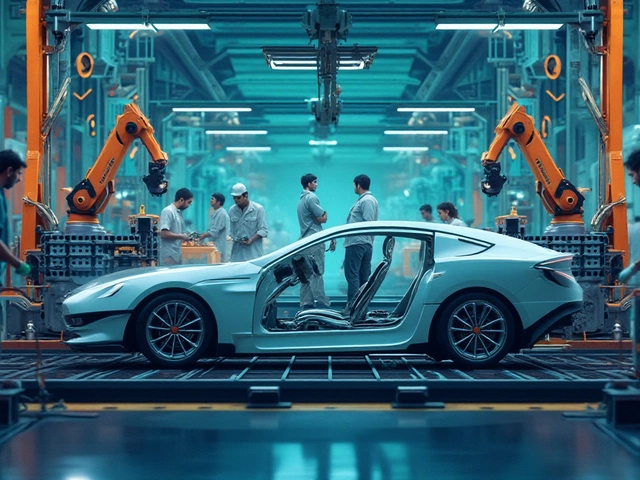

Food units aren't just random buildings. They have layouts designed for maximum efficiency and hygiene. Picture massive assembly lines, machines whisking, mixing, and packaging at the speed of light. Some units use advanced robots and automation to make everything smoother, especially in larger facilities. The aim is simple: accommodate massive consumer demand without compromising quality.

Whether it's creating everyday groceries or innovative new food products, food processing units are pretty much the unsung heroes in your eating experience. Stay tuned to learn how different types kick into gear to get those snacks, meals, and ingredients into your hands.

Different Types of Food Processing Units

Let's dig into the nitty-gritty of food units and explore the different types that exist. In the grand world of food processing, these units may vary in size, function, and the type of foods they handle, but each plays a crucial role in packaging up that breakfast cereal, rolling out pasta, and even bottling your favorite ketchup.

Dairy Processing Units

Picture vast silos filled with milk. Dairy units often pasteurize milk, turn it into cheese, butter, and yogurt, and package it all. Their job doesn't end at processing; they also ensure products are safe and taste good.

Fruit and Vegetable Processing Units

Think juicing, canning, and freezing. These units take fresh produce and make them last longer, often through processes like drying or converting them into jams and sauces. Here, the main goal is to preserve the nutritional value and flavor of fruits and veggies.

Meat Processing Units

These units are where the magic happens for making your favorite hot dogs or deli slices. From cutting to curing and packaging, they handle various meats. Safety and hygiene are super important here, given the nature of meats.

Grain and Cereal Processing Units

Every loaf of bread starts its journey in these units. They work on milling grains into flour, preparing breakfast cereals, and even crafting your go-to pasta. The focus here is on texture, quality, and storage.

Bakery and Confectionery Units

If you love cakes and chocolates, you have these units to thank. They whip up sweet treats, ensuring consistent taste and texture. Baked goods and candies involve a wide range of techniques, from baking to chocolate tempering.

Each food unit specializes in processes that suit the particular product, aiming for efficient production while keeping quality and safety at the forefront. It's an incredibly varied and fascinating industry, reflecting the diversity of our diets.

How Food Units Impact Quality and Safety

Food processing units play a key role in maintaining the quality and safety of our food. Ever wonder how a can of beans stays fresh for months? It's all thanks to these units ensuring everything is done by the book.

The first step is stringent hygiene protocols. Each food unit follows strict cleaning schedules to prevent any cross-contamination. Workers wear protective gear, and machines are regularly sterilized. Keeping germs at bay is a priority.

Quality Control Measures

Quality checks are part of the daily drill in food units. These aren't left to chance. Inspections happen at every stage of production, from raw materials to finished products. It's like having an eagle-eyed guard on duty, ensuring that food meets specified standards.

Remember the last time you opened a packet of biscuits with uniform texture and perfect crunch? That consistency isn't accidental. Food units use specific machines to ensure each product is just right, kicking out any that don't make the cut.

Ensuring Safety Standards

Safety regulations are another biggie. Each food processing unit has to comply with local and international food safety standards. These guidelines dictate everything from permissible pesticide residue levels to food contact material safety, ensuring that what lands on your plate is safe to eat.

| Check | Purpose |

|---|---|

| Hygiene Inspection | Prevents contamination |

| Quality Testing | Ensures product consistency |

| Safety Audits | Compliance with regulations |

Thanks to technological advancements, many units now use automated systems for quality checks and safety compliance. This enhances precision and reduces human error, increasing efficiency and trust in the products.

In summary, food units are like the unsung heroes that make sure everything from the milk in your cereal to the ingredients for dinner is safe and reliable. Next time you're gnawing on that piece of steak, you know someone out there made it safe for you to enjoy.

Technological Innovations in Food Processing

Technology is shaking up the way food processing works, making the industry faster, safer, and more efficient. We're talking about leaps in automation, new preservation methods, and data-driven decision-making that's turning traditional practices upside-down.

The Rise of Automation

Gone are the days of manual labor dominating food factories. Nowadays, robotic arms and automated systems handle everything from sorting and packaging to cooking and canning. This automation means fewer human errors, reduced labor costs, and increased output.

"With automation, food units can focus more on innovation and less on repetitive tasks," says Georgia Tech researcher Emily White.

Smarter Safety Measures

Ensuring food safety is critical, and technology is stepping up. Advanced sensors on production lines can detect contaminants that would otherwise slip through. Imagine systems that not only spot bacterial spores but also self-adjust to improve quality without human intervention.

Data-Driven Decisions

Food units are also becoming data whizzes. With the help of sophisticated analytics, they can predict demand trends, optimize production schedules, and minimize waste. Using smart logistics, these units make sure your favorite treats hit the shelves just in time.

Innovative Preservation Techniques

Nobody wants their food to go bad, and new tech is improving shelf-life dramatically. High-pressure processing (HPP) and pulsed electric fields are here to replace the traditional heat-pasteurization methods, keeping food fresh longer without sacrificing taste or nutrition.

Tech improvements weren't just nice-to-haves; they've become crucial. By incorporating these advancements, food units are doing more with less, and that's good news for both our plates and our planet.

Challenges and Future of Food Units

Food units are in a constant state of evolution. As the demand for processed food rises, processing units face several hard-hitting challenges. They need to meet ever changing consumer preferences, tighter regulatory compliance, and are under pressure to adopt more sustainable practices.

Keeping Up with Consumer Demands

Today's consumers want it all – flavor, convenience, and health, all packed into their food products. This means food units must keep innovating to blend taste with nutrition. Plus, there's a rising expectation for plant-based and allergen-free products. Meeting these demands is no small feat.

Regulations and Compliance

Food safety regulations are as numerous as they are critical. Every food unit must be meticulous in tracking the quality and safety of products they churn out. A hiccup here can lead to huge recalls and a severe dent in public trust. As Stewart Martin, a renowned expert in food quality, notes,

"Food processing units must navigate a labyrinth of compliance, with regulations that can change overnight."

Sustainability and Environmental Impact

Given the environmental impact of large-scale food production, there’s a push for more sustainable practices. Reducing waste, improving energy efficiency, and sourcing sustainable ingredients are top priorities. Many food units are investing in greener technologies to reduce their carbon footprint and align with global sustainability targets.

Technological Innovations

Tech is a big game changer. Automation, AI, and IoT are transforming how food processing is done. From improving precision in production processes to enhancing pack-and-sort operations, these advancements are reshaping the industry landscape.

Here's a quick rundown of potential future directions for food units:

- Smart Manufacturing: Real-time monitoring of production lines for efficiency boosts.

- Biodegradable Packaging: Reducing plastic waste.

- 3D Printed Foods: Customizable food products made to individual taste and nutrition needs.

Despite the challenges, the food units sector shows incredible resilience. By pushing for cleaner, more innovative practices, they’re laying out a future that promises both delicious and responsible eating options. There's no doubt that food processing will continue to adapt as the world and its appetites evolve.