SME Manufacturing Qualifier

| Region | Employee Limit | Revenue Limit |

|---|---|---|

| Canada | ≤ 500 | ≤ CAD 50M |

| United States | ≤ 500 | ≤ USD 50M |

| European Union | Small ≤ 50, Medium ≤ 250 | Small ≤ €10M, Medium ≤ €50M |

| Australia | ≤ 200 | ≤ AUD 50M |

Enter your business details and click "Check SME Status" to see if your company qualifies.

Key Takeaways

- SME stands for Small and Medium-sized Enterprise, defined by employee count or revenue.

- In manufacturing, SMEs make up about 90% of firms and generate roughly 40% of industry output.

- Canadian SMEs benefit from tailored government programs, tax credits, and export assistance.

- Common hurdles include access to capital, regulatory compliance, and skilled‑labor shortages.

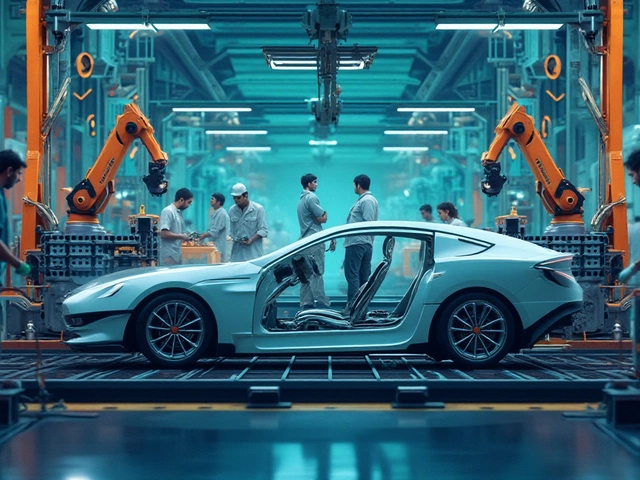

- Adopting Industry4.0 technologies, exploring new markets, and leveraging certification schemes can accelerate growth.

What Exactly Is an SME in Manufacturing?

When people talk about a SME a Small and Medium-sized Enterprise that operates in the production of goods, they’re referring to a business that falls below a certain size threshold. In Canada, a manufacturing SME typically has fewer than 500 employees or annual revenues under CAD50million. The definition mirrors the European Union’s split of 1‑49 employees for “small” and 50‑249 for “medium”, while the United States uses a 500‑employee ceiling for the manufacturing segment.

Why does the definition matter? Because eligibility for financing, tax incentives, and procurement programs hinges on those numbers. A firm that barely crosses the 500‑employee line may lose access to a suite of supports designed specifically for smaller players.

Size Criteria Across Major Markets

| Region | Employee Limit | Revenue Limit |

|---|---|---|

| Canada | ≤500 | ≤CAD50M |

| United States | ≤500 | ≤USD50M |

| European Union | Small ≤50, Medium ≤250 | Small ≤€10M, Medium ≤€50M |

| Australia | ≤200 | ≤AUD50M |

These thresholds are not arbitrary; they reflect each economy’s industrial structure and policy goals. For a mid‑size Canadian metal‑fabrication shop with 120 staff and CAD7million in sales, the numbers place it squarely in the “medium” category, unlocking specific funding streams.

Why Manufacturing SMEs Matter

Manufacturing SMEs are the backbone of the national economy. According to the latest Statistics Canada the federal agency that tracks economic data for Canada, they account for roughly 90% of all production firms and employ over 1.2million workers - about 45% of the sector’s total workforce.

Beyond jobs, these firms drive innovation. A 2023 survey of 1,200 Canadian manufacturers found that 63% of product breakthroughs originated in firms with fewer than 200 employees. Smaller teams can pivot faster, experiment with niche materials, and adopt new processes without the bureaucracy that stalls larger corporations.

Export contributions are another hidden strength. While large multinationals dominate high‑value aerospace and automotive exports, SMEs collectively ship an estimated CAD30billion of goods overseas each year, ranging from specialty plastics to custom‑machined components.

Common Challenges Faced by Manufacturing SMEs

Running a production line with limited resources presents a unique set of hurdles:

- Financing gaps: Traditional banks often view capital‑intensive equipment purchases as risky, leading to higher interest rates or longer approval times.

- Regulatory compliance: Meeting ISO9001 quality standards or navigating Canada’s Hazardous Materials Regulations can strain small compliance teams.

- Talent shortages: Skilled machinists and CNC programmers are in high demand, especially in Ontario’s industrial corridors.

- Technology adoption: Investing in Industry4.0 tools - such as IoT sensors, predictive maintenance software, and digital twins - requires upfront spend that many SMEs postpone.

- Market access: Competing against larger suppliers for government contracts or multinational buyer agreements can be daunting without a dedicated sales force.

Support Programs and Funding Options

Governments at the federal, provincial, and municipal levels have built a safety net for manufacturers that fit the SME profile. Here are the most impactful schemes for a Canadian context:

- Canada Manufacturing Innovation Fund (CMIF) Provides up to 50% co‑funding for technology adoption projects. Eligible projects include robotics integration, energy‑efficient equipment, and advanced material research.

- Ontario Business Grants (OBG) Targeted at SMEs in the province, offering CAD25000-150000 for workforce training and export market development.

- Export Development Canada (EDC) Financing Provides credit guarantees and insurance for manufacturers seeking overseas customers.

- Industrial Research Assistance Program (IRAP) Offers advisory services and up to CAD200000 in project funding for R&D.

These programs share a common requirement: documented proof that the business meets the SME definition. That’s why keeping accurate employee and revenue records is essential.

Growth Strategies Tailored for Manufacturing SMEs

To move from survivorship to sustainable growth, a manufacturer can focus on three pillars:

- Digitalisation. Start with low‑cost IoT sensors on critical machines to capture uptime data. The insights can guide predictive maintenance schedules, cutting downtime by up to 15% as shown in a 2022 Ontario case study.

- Export diversification. Use EDC’s market‑entry toolkit to identify niche markets where your product’s unique specifications meet local demand. For example, a Toronto‑based metal‑stamping shop found a lucrative niche in Brazil’s automotive aftermarket.

- Strategic partnerships. Align with universities or research centres for joint development projects. The University of Waterloo’s Advanced Manufacturing Lab partnered with a 80‑person SME, resulting in a patented low‑cost alloy that reduced material costs by 12%.

Each pillar reduces reliance on a single revenue stream and builds resilience against supply‑chain shocks-something the COVID‑19 pandemic highlighted for many small producers.

Quick Checklist: Does Your Business Qualify as a Manufacturing SME?

- Are you operating in a production or assembly environment?

- Is your full‑time staff count ≤500?

- Does your annual revenue stay below CAD50million?

- Do you have a formal business registration in Canada?

- Can you demonstrate compliance with relevant industry standards (e.g., ISO9001, CSA‑P‑3402 for machining)?

Answering “yes” to all five points typically qualifies you for the majority of SME‑focused incentives.

Future Outlook: SME Manufacturing in 2025 and Beyond

Looking ahead, three macro trends will reshape the landscape:

- Decarbonisation pressure. Canada’s net‑zero target pushes manufacturers toward greener processes. SMEs that adopt energy‑efficient equipment now will qualify for carbon‑tax rebates later.

- Supply‑chain re‑localisation. Companies are reshoring production to reduce geopolitical risk. This creates opportunities for local SMEs to become Tier‑2 or Tier‑3 suppliers for larger OEMs.

- Talent pipelines. Apprenticeship programs are expanding, especially in Ontario’s “Manufacturing Skills Initiative”. SMEs that engage early with trainees gain a ready‑made workforce.

Staying aware of these forces and aligning your growth plan accordingly can turn potential disruption into a competitive edge.

Frequently Asked Questions

What defines a ‘medium’ manufacturing SME in Canada?

A medium SME has between 101 and 500 employees or annual revenues ranging from CAD10million to CAD50million. The exact cut‑off depends on whether the regulator uses an employee‑based or revenue‑based metric.

Can a service‑oriented business be considered a manufacturing SME?

Only if at least 50% of its revenue comes from producing tangible goods. Pure‑play service firms fall outside the manufacturing definition.

How do I apply for the Canada Manufacturing Innovation Fund?

First, register on the Innovation, Science and Economic Development Canada portal. Then submit a detailed project proposal, including cost breakdown, expected technology outcomes, and a timeline. Applications are reviewed quarterly.

Is ISO 9001 mandatory for Canadian manufacturing SMEs?

No, it’s not a legal requirement, but many customers and government contracts demand it. Achieving ISO 9001 can also streamline internal processes.

What are the biggest cost‑saving areas for a manufacturing SME?

Energy efficiency upgrades, predictive maintenance, and reducing scrap rates through lean practices typically deliver the highest ROI within 12‑18months.