Made in USA Cost Calculator

Compare USA vs. Overseas Manufacturing Costs

See how the actual cost and value of products compares, based on the article's insights about U.S. manufacturing.

It’s a common saying: "Nothing’s made in America anymore." You hear it in politics, on TV, in memes. But if you’ve walked through a hardware store, visited a hospital, or driven a pickup truck lately, you’ve probably used something made right here in the U.S.-and you didn’t even realize it.

What’s actually being made in the U.S. today?

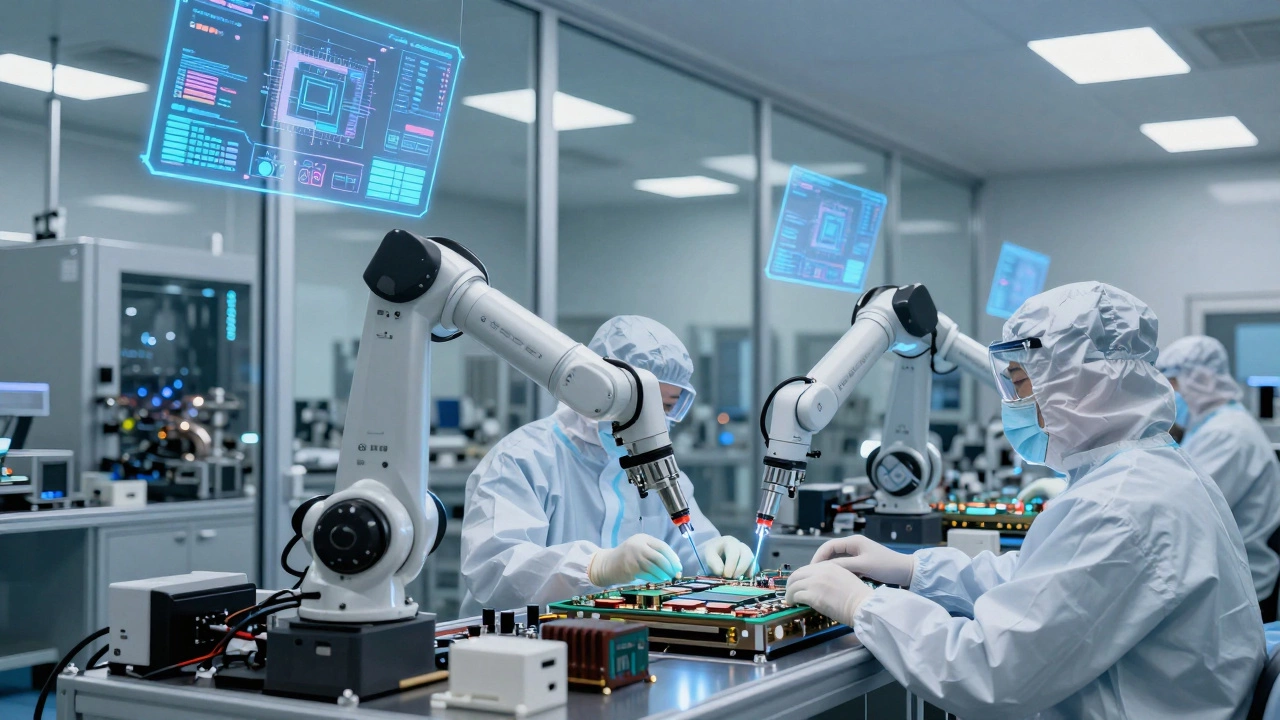

The truth is, the U.S. still manufactures more than $2.3 trillion worth of goods every year. That’s more than any country in Europe, and second only to China in total output. But it’s not the same kind of manufacturing as 30 years ago. Factories don’t just churn out T-shirts and toys anymore. They build jet engines, semiconductors, medical devices, and advanced batteries.

Take Boeing. Even though many parts come from overseas, the final assembly of the 737, 777, and 787 happens in Washington State. Every single one. The same goes for General Electric’s H-class gas turbines-made in Lynn, Massachusetts-and Lockheed Martin’s F-35 fighter jets, assembled in Fort Worth, Texas. These aren’t small operations. They employ thousands, require precision engineering, and rely on U.S.-based supply chains.

And it’s not just big names. In Ohio, a small company called First Solar is producing photovoltaic panels using American-made materials and labor. In Indiana, Owens-Illinois makes glass bottles for craft beer and pharmaceuticals. In Alabama, Tesla produces the Model Y and battery packs at its Gigafactory. These aren’t exceptions-they’re part of a growing trend.

Why did people think manufacturing left for good?

The decline of American manufacturing was real-but it was mostly about scale, not disappearance. Between 1990 and 2010, the U.S. lost over 5 million manufacturing jobs. That’s because factories became more efficient. One machine now does the work of ten people. A factory that made 10,000 TVs in 1995 might make 100,000 today with half the workers. So while output stayed high, employment dropped.

At the same time, cheap labor overseas pulled away low-value production: plastic toys, basic clothing, simple electronics. But those were never the high-margin, high-skill products that drive innovation. What’s been overlooked is that the U.S. doubled down on what it does best: complex, capital-intensive, high-tech manufacturing.

Think of it this way: China makes your phone. But the chip inside it? Likely designed in California and made in Arizona. The titanium in your hip replacement? Melted and forged in Pennsylvania. The lithium-ion battery in your electric car? Assembled in Georgia using materials mined in Nevada and processed in Tennessee.

Government schemes are bringing manufacturing back

The shift didn’t happen by accident. Since 2021, the U.S. government has poured over $500 billion into reshoring manufacturing through laws like the CHIPS and Science Act, the Inflation Reduction Act, and the Bipartisan Infrastructure Law.

The CHIPS Act gave $52 billion in direct funding and tax credits to companies building semiconductor plants in the U.S. Since then, Intel, TSMC, Samsung, and Micron have announced over $200 billion in new investments. TSMC is building two new fabs in Arizona. Intel is expanding in Ohio. These aren’t just factories-they’re entire ecosystems of suppliers, engineers, and skilled tradespeople being rebuilt from the ground up.

The Inflation Reduction Act ties tax credits to American-made content. For electric vehicles, you now get a $7,500 credit only if the battery is assembled in North America and contains a certain percentage of U.S.-mined minerals. That’s pushing companies like Ford and General Motors to build battery plants in Michigan, Tennessee, and North Carolina. In 2023 alone, the U.S. added more than 10 new battery gigafactories.

And it’s not just tech. The Infrastructure Law funded over $1 billion for domestic production of clean energy components-wind turbine blades, solar inverters, and grid-scale batteries. Companies like Vestas and GE Renewable Energy are opening factories in Colorado, Iowa, and Texas because the government is making it financially smarter to build here than to import.

It’s not just big companies-small manufacturers are thriving

While the headlines focus on Tesla and Intel, thousands of small and mid-sized manufacturers are quietly expanding. In rural Pennsylvania, a family-owned company called Carpenter Technology produces specialty steel for aerospace and medical implants. In North Carolina, Honeywell makes industrial sensors in a 100-year-old plant that just added 200 new jobs.

These businesses aren’t getting billions in subsidies. But they’re benefiting from state-level programs: tax breaks for hiring skilled workers, grants for automation upgrades, and workforce training funded by the Department of Labor. In Wisconsin, the state offers up to $50,000 per job created in advanced manufacturing. In Georgia, manufacturers get free access to engineering labs at state universities.

And here’s the kicker: these small factories are more resilient. During the pandemic, when global supply chains broke down, U.S.-based makers kept producing. Hospitals got ventilators. Pharmacies got syringes. The military got spare parts. That’s why local governments are now prioritizing domestic supply chains-not just for jobs, but for national security.

What’s still being made overseas-and why

Of course, not everything is made here. You won’t find American-made smartphones, cheap plastic toys, or fast fashion. Why? Because those products rely on labor-intensive, low-margin production. The U.S. doesn’t compete on price for those items-it competes on quality, speed, and reliability.

But even here, things are changing. Some companies are bringing back simple assembly. In 2024, Apple started assembling a small line of AirPods in Texas. It’s not replacing China, but it’s a signal: if you can automate the process and control the supply chain, it’s worth doing it closer to home.

And consumers are noticing. A 2025 survey by the National Association of Manufacturers found that 73% of Americans are willing to pay up to 15% more for products labeled "Made in USA." That’s driving brands like Patagonia, Levi’s, and Yeti to restructure their supply chains to meet demand.

What does this mean for the future?

The U.S. isn’t going back to the 1950s. We won’t have factories on every corner making pencils and socks. But we’re building something new: a smarter, more resilient manufacturing base. One that combines automation, advanced materials, and skilled labor to make things that matter.

By 2030, the U.S. could add 2 million new manufacturing jobs-not because we’re going backward, but because we’re upgrading. The government isn’t just subsidizing factories; it’s rebuilding the entire ecosystem: from vocational schools training welders and CNC operators, to research labs developing next-gen alloys, to logistics networks that can deliver parts in hours, not weeks.

The question isn’t whether anything is made in the U.S. anymore. The real question is: what will we make next?

Is the U.S. still a major manufacturer globally?

Yes. The U.S. is the second-largest manufacturer in the world, behind China, producing over $2.3 trillion in goods annually. It leads in high-value sectors like aerospace, pharmaceuticals, semiconductors, and defense equipment. While it no longer dominates low-cost consumer goods, its output in advanced manufacturing continues to grow.

What government programs are helping bring manufacturing back?

The CHIPS and Science Act provides $52 billion in funding and tax credits for semiconductor production. The Inflation Reduction Act offers tax credits for electric vehicles and clean energy components made in the U.S. The Bipartisan Infrastructure Law funds domestic production of wind turbines, batteries, and grid equipment. States also offer grants, workforce training, and tax breaks to attract manufacturers.

Are American-made products more expensive?

Sometimes, but not always. Labor costs are higher, but automation, faster shipping, and fewer supply chain delays often balance the price. Many consumers now pay more for quality and reliability-73% say they’d pay up to 15% extra for U.S.-made goods. In industries like medical devices and aerospace, American-made products often cost less over time because they last longer and have better support.

What kinds of jobs are being created in U.S. manufacturing?

Most new jobs aren’t in assembly lines. They’re in robotics maintenance, quality control, CNC programming, supply chain logistics, and engineering. The average manufacturing job today pays $28 an hour-over $58,000 a year-with benefits. Many companies partner with community colleges to train workers in just six months.

Can small businesses benefit from these government programs?

Absolutely. While big companies get headlines, state and local programs offer grants, tax credits, and technical support to small manufacturers. Programs like the Manufacturing Extension Partnership (MEP) provide free consulting to help small firms adopt automation, improve efficiency, and access new markets. Many have used these resources to win contracts with larger suppliers.