Plastic Manufacturers: Trends, Challenges & Opportunities

When dealing with plastic manufacturers, companies that turn polymer resins into everyday products such as bags, bottles, films and building components. Also known as polymer fabricators, they form the backbone of many supply chains. Their performance is closely tied to plastic export, the cross‑border flow of finished plastic goods that fuels global demand and to the rise of manufacturing startups, new ventures that leverage lean tools and digital design software to launch quickly. In addition, global trade, the network of tariffs, logistics and market agreements that move goods worldwide shapes how these firms plan capacity and pricing.

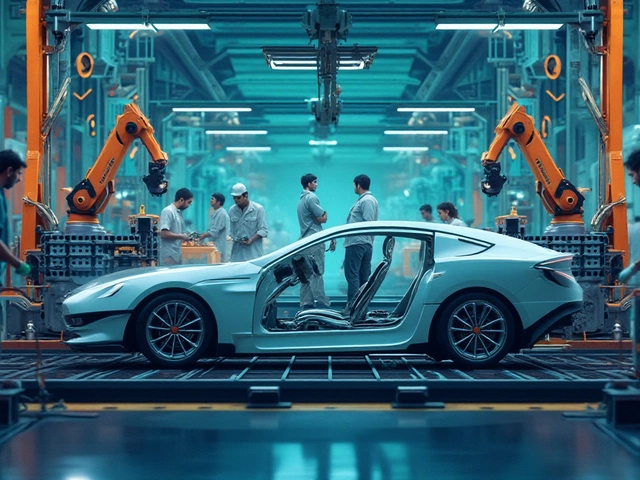

One of the biggest levers for plastic manufacturers is raw material sourcing. Polyethylene, polypropylene and PVC are sourced from petrochemical complexes, so price swings in oil directly affect production costs. Over the past three years, export data shows that Asia, especially China, dominates the market, moving over 30 million tonnes annually. However, India's push for higher-value polymer products is shifting the export mix toward engineered plastics used in automotive and electronics. This shift forces manufacturers to adopt advanced extrusion and injection molding lines, which boost consistency but require sizable capital. Understanding these export trends helps firms decide whether to focus on volume‑driven commodity grades or niche, high‑margin specialties.

Key Factors Shaping Plastic Manufacturing Today

Start‑ups play a surprisingly big role in the sector. A recent survey of 120 new factories revealed that 78 % rely on two essential software brands for product design and process simulation. These tools cut prototype time by half and let small teams compete with legacy players. At the same time, sustainability is no longer an afterthought. Regulations in Europe and North America now demand recycled content targets of 30 % for packaging plastics. Manufacturers respond by integrating closed‑loop recycling lines and by experimenting with bio‑based polymers derived from sugarcane or algae. The ripple effect is clear: greener feeds lower carbon footprints, but they also introduce new quality control steps that older plants must master.

Looking ahead, the intersection of trade policy, technology adoption and environmental pressure will define the next wave of growth. Readers will find deep dives into export statistics, startup toolkits, and sustainability roadmaps in the posts below. Whether you’re a plant manager, a new venture founder or an investor tracking the sector, the collection offers actionable insights that go beyond headlines. Dive in to see how these dynamics play out across real‑world case studies and expert analyses.

Who Dumps Plastic in the Ocean? Uncovering the Real Culprits

Explore who really dumps plastic into our oceans, from manufacturers to illegal dumpers, and learn actionable steps to stop the flow.

View More